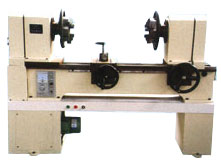

Straight guide design, chain synchronous drive, make the lathe concentric synchronous operation to highest accuracy the glass processing needed.

Guide rail use the traditional manual scraping, active machine head and rail point contact, can reduce abrasion, prolong the service life of the lathe.

Equipped with a fire workbench , and an adjustable flame holder, convenient in the processing of the flame position adjustment.

This lathe increased the height of the center than traditional lathe, and extending the processing range between chucks, so that the lathe processing capacity reached the largest user requirements.

Increased the overall weight of equipment to achieve the best stability of the equipment operation process.

| Distance of spindle center to guide rail | 300mm |

| Distance between spindle chuck plane | 670mm |

| Spindle aperture | 60mm |

| Three claws chuck workable diameter | 4-200mm |

| Parallelism between axes of lathe head and guide rail Unequal height between principal axis of the two lathe Moving distance of the left and right lathe head |

0.04 0.05 ±0.03 |

| Rotate speed of principal axis | 24-240r/min |

| Power of main motor | 380V 50Hz 0.55KW |

| Lathe size | 1650×470×1190mm |

| Weight | 550KG |

| Lathe length | 1600mm |

| Principal axis and workbench | 260mm |